Manufacturing Capabilities

Thanks to 40-years experience and investments it has gained, TEI produces engine parts for many military and civil aircraft today; and accommodates the manufacturing capabilities needed by the industry in this area. Besides conventional production methods, Nadcap-accredited special processes and non-destructive inspections are among the specialties of TEI thanks to these capabilities. Moreover, TEI applies Lean Production and 6 Sigma approaches across all stages of its manufacturing processes with a strong commitment to quality.

Machining

Aiming to become a leading part manufacturer in global aviation industry, TEI has a wide range of capabilities in machining processes and constantly improves its manufacturing capabilities in this field by investing in advanced technologies.

Capabilities of TEI:

- CNC Turning

- CNC Milling

- CNC Grinding

- Jig Grinding

- Curvic Coupling Grinding

- Broaching

- Gear Shaping (Spline)

- Automated Edgebreaking / Deburring (Robotic Machining, High Speed 6-Axis Machining, Abrasive Brushing at Special Design Workstations)

- Abrasive Flow Machining

- Vibratory Machining

TEI is capable of manufacturing high quality and highly sensitive products required by the aviation industry thanks to its capabilities.

Fabrication

In addition to our existing capabilities for manufacturing and operational processes of sheet metal parts, TEI invests in new processes and automatic applications in line with the new developments in the industry to meet the high-standard requirements of the aviation industry in fabrication field. Capabilities of TEI: In addition to our existing capabilities for manufacturing and operational processes of sheet metal parts, TEI invests in new processes and automatic applications in line with the new developments in the industry to meet the high-standard requirements of the aviation industry in fabrication field.

Capabilities of TEI:

- GTAW (Gas Tungsten Arc Welding) [6-Axis Automatic and 4-Axis Semi-Automatic Benching, Manual Welding]

- Robotic Spot Resistance Welding

- Seam Resistance Welding

- Electro-beam Welding

- Cold Forming [300-ton Hydraulic Press]

- Cutting and Bending [Expand and Roll Machines]

- Rivet Joining

- Drilling [Eccentric Press]

- Air Flow Measurement [Flow Measurement and Effective Area Measurement]

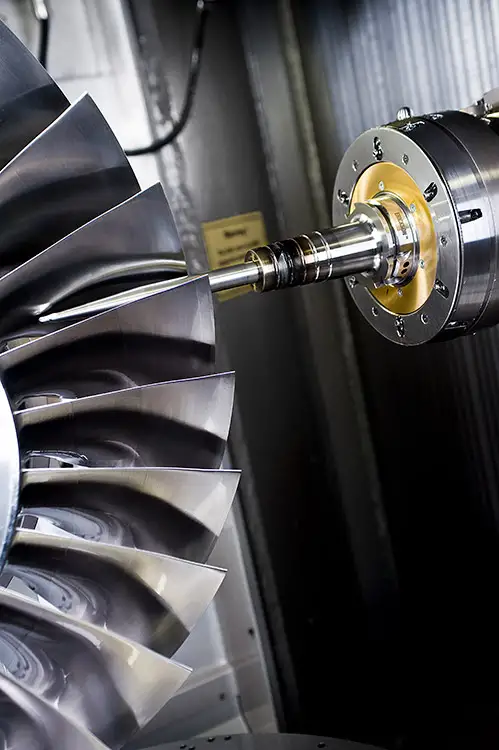

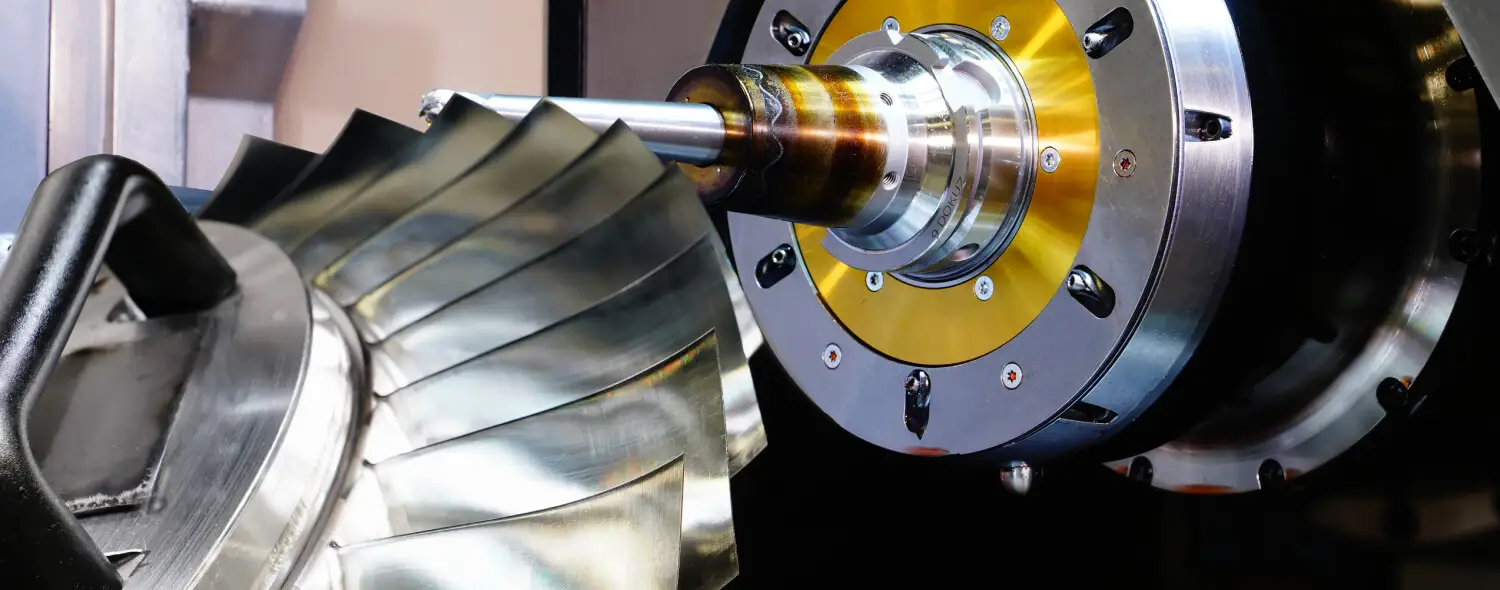

Blisk Manufacturing

Blisks are the integrated version of compressor disks and blades which are used in turbine engines. Blisks are used in compressors to minimize the engine weight, to maximize the aerodynamic performance and to ensure high fuel saving. Blisks are hi-tech product components, requiring innovative technologies, production techniques and equipment for manufacturing. TEI is one of the few global aviation companies equipped with the technological infrastructure and competencies necessary for blisk manufacturing.

Blisk Manufacturing / Measurement Capabilities

- Inertia Welding

- Blade Manufacturing Technologies

- High Speed Blade Milling

- ECM (Electrochemical Machining)

- Automated Surface Finishing Technologies

- Robotic Deburring

- Vibratory Finishing

- Simultaneous Shot Peening

- Noncontact Blade Inspection

- Ultrasonic Inspection

High Speed Blade Milling: Blisks used in new technology aircraft engines are typically costly and difficult to produce because of the complex geometry of their structure. TEI is equipped with the software, machine and equipment infrastructure, blade milling strategies development capability and implementation experience necessary to produce blisk blade surfaces through the high-speed milling method. Specially-designed 5-axis machines with high machine dynamics and precision are used to be able to produce blisk blade surfaces of different sizes and having different materials through the high-speed milling method.

ECM (Electrochemical Machining): Electrochemical Machining (ECM) process is a non-conventional, cost-effective manufacturing method used in formation of aerodynamic blade surfaces with complex geometries for blisks. ECM process is faster than conventional milling methods, and it does not cause any damage or stress on the surface and generates a perfect surface quality. ECM material removal rate is independent of the material hardness. TEI has a 6-axis CNC ECM machine and ECM electrolyte conditioning facility (Brewery), which provide us with the capability of processing blisk blades by ECM process.

Inertia welding is a process, which is used to weld several rotating parts in turbine engines. In this process, one workpiece is fixed in a rotating flywheel and the other is fixed on the body. The energy required for the process is stored in the flywheel which is rotated at a pre-determined rate. The friction between the rotating and stationary workpieces in relative motion to one another and the high heat generated through this friction provide the energy required for welding. While processing times are quite short in inertia welding process, the process shows a high repeatability. In addition, parts with different materials may be welded with this process.

TEI has two inertia welding machines with different capacities. In these machines, Fan Disc, Spool, Blisk and HPT Disc parts, which belong to different engine programs, are welded with inertia welding process. TEI is among the important companies, which has Nadcap certification in Inertia Welding process.

Measurement Capabilities

With a quality approach based on flight safety and customer satisfaction, TEI continues to make a name for itself every day and build confidence among all stakeholders with our sustainable achievements thanks to our employees, our most valuable asset, by integrating high-tech 2D / 3D contact/non-contact, fixed/mobile quality control equipment into our business as well as embedding a philosophy of constant development in everything we do and always aiming for the best. More than 90% of the equipment qualification is carried out by the expert and certified personnel of TEI at the mechanical and electronic calibration laboratories established at TEI in accordance with the sensitivity, accuracy and traceability criteria of the aviation industry.

Non-Destructive Testing

- Ultrasonic Testing

- Eddy Current Testing

- Fluorescent Penetrant Inspection

- Magnetic Particle Inspection

- Radiographic (X-Ray) Inspection

Measurement Technologies

- Dimension and Form Inspection Technologies

Laboratory Tests

- Metallographic Assesment

- Macro Hardness Measurement

- Micro Hardness Measurement

- Particle Size Measurement

- Physical / Chemical Analysis

Special Processes

In special processes, which modify or change the inherent material properties of a part and which cannot be fully evaluated by non-destructive methods, innovative manufacturing techniques, cutting-edge technology and the highest quality standards are used

- Robotic Thermal Spray Coatings (Coating of direct and non-line-of-sight surfaces of complex parts for protection against wear, corrosioni high temperatures; obtaining abradable and abrasive properties and for dimensial restoration with plasma HVOF and combustion flame techniques)

- Shotpeening

- Simultaneous Shotpeening

- Inertia Welding

- Ultrapolishing (Airfoil Surfaces)

- Vacuum Heat Treatment

- Vacuum Brazing

- Chemical Processes

- Robotic Anticorrosion Coating Applications

- Sermetel Coating

- Nickel Electroplating

- Dry Lubricant Applications

- Black Oxide Coating

- Macro Etching

- Titanium Macro Etching

- Blue Etch Anodizing

- Alkaline Cleaning & Titanium Cleaning

- Chemical Milling

- Non-Traditional Manufacturing Methods

- Sink EDM

- Wire EDM

- Fast Hole EDM

- STEM Drilling

- Electrochemical Machining

- Electrochemical Grinding

- Laser Cutting and Drilling